Refractories for hot-metal ladle lining

Bricks are intended for hot-metal ladle lining and other thermal units.

Technical characteristics

| Rate for grade | |||||

|---|---|---|---|---|---|

| ShChU-37 | ShChU-37U | MKRCHU-45 | MKRCHU-55 | MKCHS-72 | |

| GOST 15635-2015 | |||||

|

Mass fraction, %: Al2O3, minimum |

|

|

|

55 4 |

over 72 1,5 |

| Compressive strength, N/mm2, minimum | 25 | 30 | 35 | 35 | 30 |

| Open porosity, %, maximum | 20 | 18 | 19 | 20 | 24 |

| Residual variation of dimensions when heating, %, maximum at 1400 °С at 1600 °С |

0,4 - |

0,2 - |

0,4 - |

-0,4 to +1,0 - |

- 1,0 |

| Thermal shock, t/cm, minimum | - | - | 4 | 4 | - |

| Refractoriness, °С, minimum | 1730 | 1730 | 1730 | 1750 | - |

| Temperature of initial softening, °С, minimum | - | - | 1400 | - | 1500 |

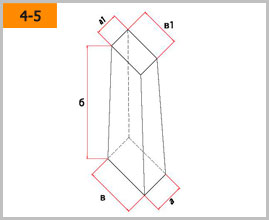

Form and dimensions

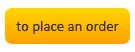

| Number of brick | Dimensions, mm | Application | |||||

|---|---|---|---|---|---|---|---|

| a | a1 | б | в | в1 | |||

| 1 | 210 | 176 | 230 | 80 | - | for working lining of cylindrical part of ladles with inside laying radius, mm | |

| 2 | 230 | 198 | 230 | 80 | - | ||

|

when one number of item is used 1130 - 1290 1350 - 1540 |

when two numbers of items are used 1290 - 1350

|

||||||

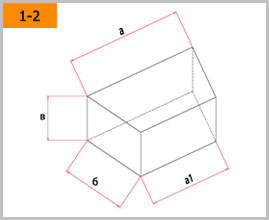

| 3 | 77 | - | 230 | 113 | 95 | for working lining of spherical bottom with inside laying radius of 1150-2150 mm | |

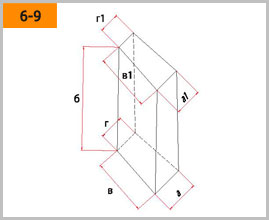

| Number of brick | Dimensions, mm | Application | |||||||

|---|---|---|---|---|---|---|---|---|---|

| a | a1 | б | в | в1 | г | г1 | |||

| 4 | 65 | 54 | 230 | 113 | 95 | - | - |

for working lining of spherical bottom with inside laying radius of 1150-2150 mm the same, when laying strong bottom |

|

| 5 | 65 | 50 | 300 | 113 | 89 | - | - | ||

| 6 | 65 | 54 | 230 | 113 | 95 | 45 | 38 |

for working lining of spherical bottom with inside laying radius of 1150-2150 mm the same, when laying strong bottom |

|

| 7 | 65 | 54 | 230 | 113 | 95 | 55 | 46 | ||

| 8 | 65 | 54 | 230 | 113 | 95 | 60 | 50 | ||

| 9 | 65 | 50 | 300 | 113 | 89 | 55 | 43 | ||

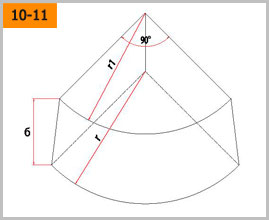

| Number of brick | Dimensions, mm | Application | |||

|---|---|---|---|---|---|

| б | r | r1 | |||

| 10 | 115 | 261,5 | 239 | for cantral part of spherical bottom with inside laying radius of 1150-2150 mm | |

| 11 | 115 | 284 | 261,5 | ||