Refractories for Rotary Kilns Used in Cement Industry

Bricks are intended for lining of rotary kilns used in cement industry and other thermal units.

Technical characteristics

| Rate for grade | ||||

|---|---|---|---|---|

| ShCU | МКRC | МLC | МКC | |

| GOST 21436-2004 |

||||

| Mass fraction of Al2O3,%: | minimum 32 | over 45 | over 62 | over 72 |

| Compressive strength, N/mm2, minimum | 25 | 30 | 25 | 30 |

| Open porosity, %, maximum | 20 | 22 | 24 | 24 |

|

Residual variation of dimensions when heating, %, maximum at: 1400 °C 1500 °C 1600 °C |

- - |

- - |

0,4 - |

- 1,0 |

| Refractoriness, °С, minimum | 1710 | 1750 | 1800 | - |

| Thermal shock resistance, heat cycles, minimum | 4 | 3 | 4 | 4 |

| Temperature of initial softening, °С, minimum | 1370 | 1400 | 1450 | 1500 |

Limit deviations of brick dimensions (mm)

| Dimensions, mm | ShCU | MKRC, МLC, МКC |

|---|---|---|

| up to 100 inc. | ±1 | ±1,5 |

| over 100 up to 200 inc. | ±2 | ±2 |

| over 200 up to 300 inc. | ±3 | ±3 |

| normal difference а-а1 | +1, -2 | +1, -2 |

Form and dimensions

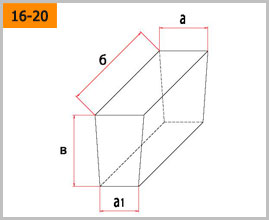

End arch brick, double-side

| Number of brick | Dimensions, mm | Application | ||||

|---|---|---|---|---|---|---|

| а | а1 | б | в | In combination with numbers | Kiln diameter, m | |

| 1 | 100 | 88 | 150 | 300 |

2 9 |

2,3-5,1 5,1-7 |

| 2 | 75 | 55 | 150 | 300 | 1 | 1,3-5,1 |

| 3 | 100 | 92 | 150 | 300 |

4 3 |

3,1-5,1 3,1-5,1 |

| 4 | 75 | 65 | 150 | 200 | 5 | 1,5-3,1 |

| 5 | 75 | 55 | 150 | 200 | 4 | 1,5-3,1 |

| 6 | 100 | 95 | 150 | 230 | 7 | 5,2-7 |

| 7 | 100 | 91 | 150 | 230 | 6, 8 | 5,2-7 |

| 8 | 120 | 113 | 150 | 230 | 7 | 5,2-7 |

| 9 | 100 | 93 | 150 | 300 | 1 | 5,1-7 |

| 10 | 100 | 93 | 200 | 300 | 11 | 5,1-7 |

| 11 | 100 | 88 | 200 | 300 | 10 | 5,1-7 |

| 12 | 100 | 91 | 200 | 230 | 13 | 5,2-7 |

| 13 | 120 | 113 | 200 | 230 | 12 | 5,2-7 |

| 14 | 100 | 92 | 200 | 200 | 15 | 3,1-5,1 |

| 15 | 75 | 65 | 200 | 200 | 14 | 3,1-5,1 |

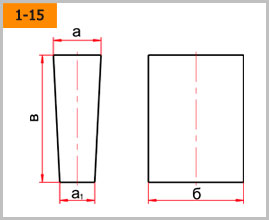

Side arch brick, double-side

| Number of brick | Dimensions, mm | Application | ||||

|---|---|---|---|---|---|---|

| а | а1 | б | в | In combination with numbers | Kiln diameter, m | |

| 16 | 100 | 94 | 200 | 160 |

17 16 |

3,1-5,4 |

| 17 | 75 | 67 | 200 | 160 | 18 | 1,6-3,1 |

| 18 | 75 | 60 | 200 | 160 | 17 | 1,6-3,1 |

| 19 | 100 | 95 | 200 | 120 | 20 | 1,8-4,9 |

| 20 | 75 | 65 | 200 | 120 | 19 | 1,8-4,9 |